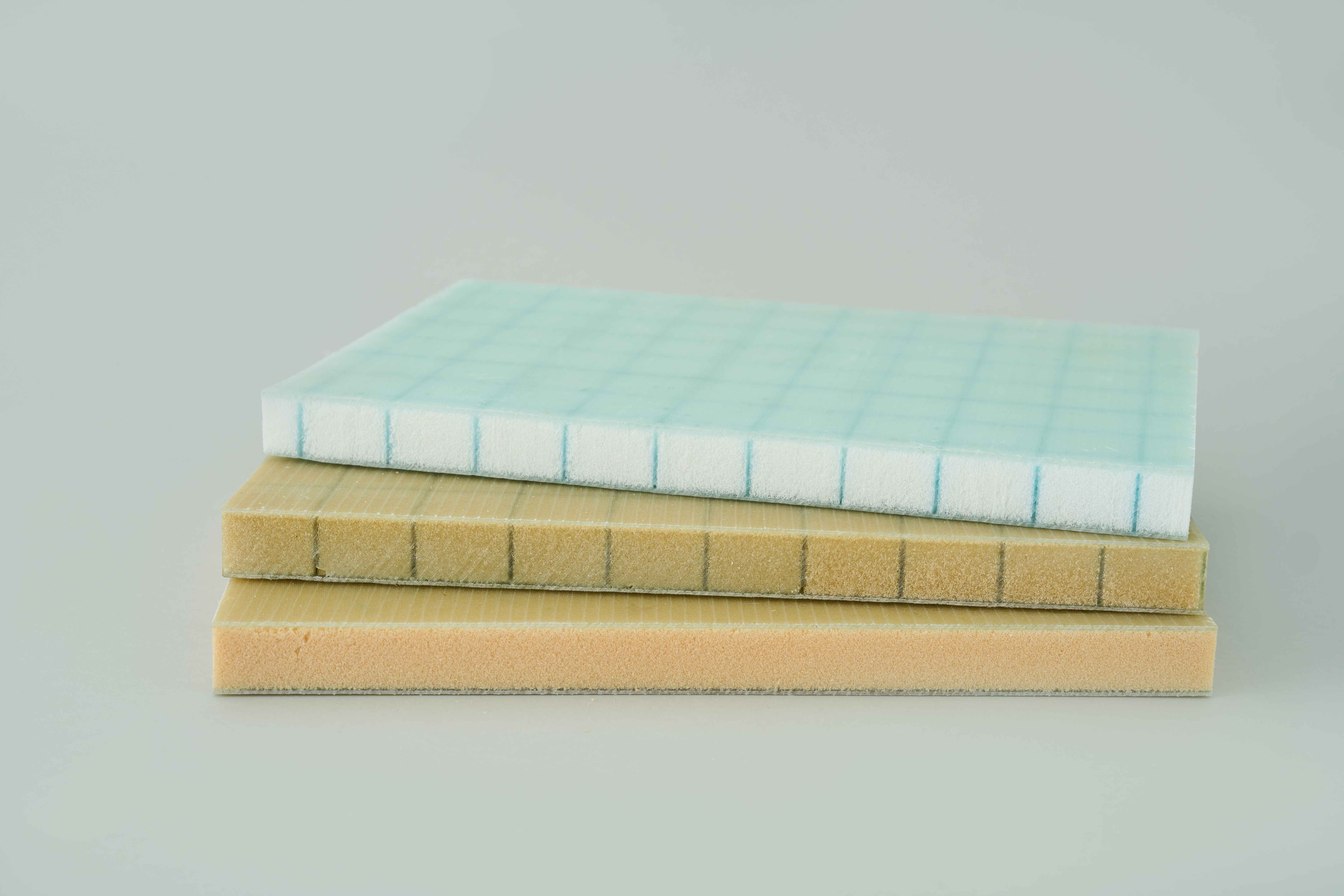

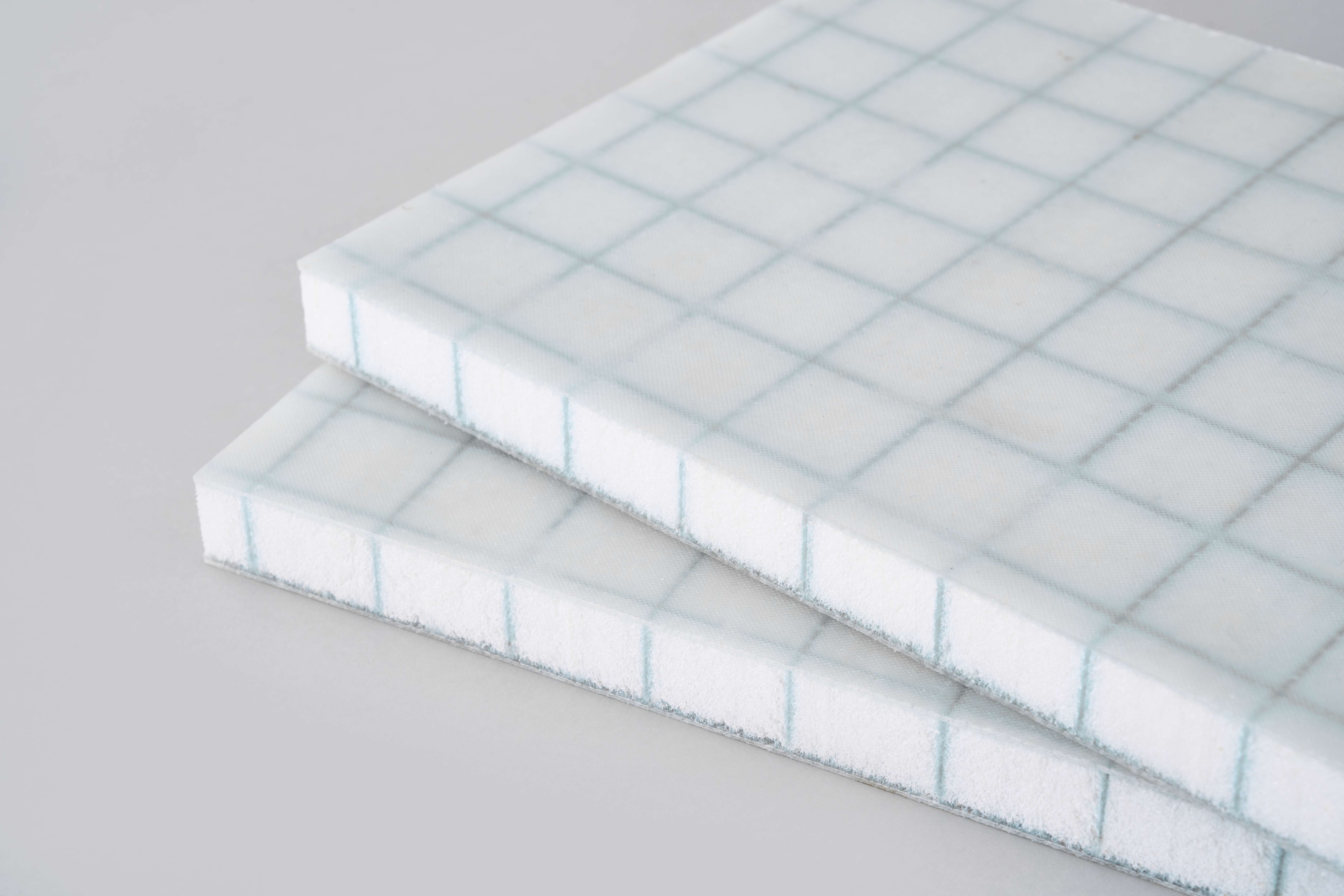

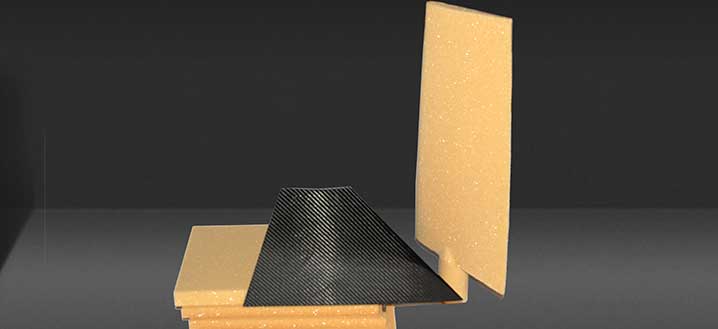

Sandwich structure

Core Material Expert -- always beyond excellence

- Products -

Products

Vicell P Series Vicell V Series Vi-balsa PET Series PI Series Vicell kits Sandwich structure Data Download

Sandwich structure

Core Material Expert -- always beyond excellence

High strength toweight ratioThe high intensityand weight ratio of core material enables it to be utilized in various areas-faster, remoter and strongereffectively load capacity or being able to reduce energy requirement-all the above mentioned characteristics can bring about betteroperational economic efficiency. | Good dynamic propertyComposite core materialcould provide great dynamic property, which makes it the ideal material that isvibration-resistant and shock-resistant in load area. |

Low water absorptionStructural foam coresare closed-cell structure which enable them to have extremely low waterabsorption, so water could not get into them in reality. | Excellent effect ofsound and heat insulationStructural foamy corematerial has excellent property of sound and heat insulation, so extrasound-insulation and heat-insulation materials that will raise the weight andcost of structural materials are not in need. |

|

Laminating craft is usual adopted when using Vicell foam as core material to manufacture sandwich structure. It is recommended to control heel block by adjusting thickness in order to avoid exceeding bubble elastic creep limit especially when solidification is underway in the mold.In order to promote foamy core material to large-load and light structure, an important way is to increase its shearing strength. Because the performance improvement of foamy core material is usually achieved through increasing density, hence it is necessary to find a way of combining fiber-strengthening with foamy core material. An structural successful method is to add a ventral structure penetrating through a 45 angle and the size can be adjusted according to the stress requirement. The interfacial property between foamy core material and thin-gauge skin can be helpful to increase structural shocking injured biliary. The interfacial property between foamy core material and thin-gauge skin can be strengthened by using z-direction fiber. According to research and application, acupuncture and sewing are effective ways of improving foamy core material. |

Follow Us